Build an Engine

Right the First time

By: Louis Misciasci

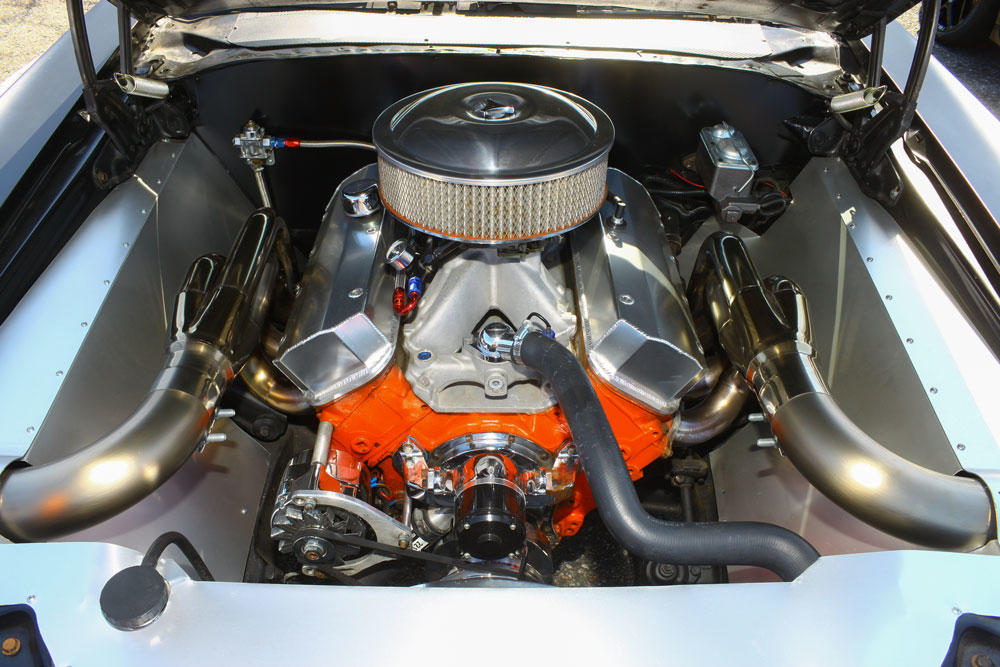

Building a new engine for your project car can be a fun, but it can also be costly. Have you ever built an engine and been disappointed with the performance? Or maybe, you just have too much money wrapped up in it? In this article we will look at things you need to consider before building an engine. Most people want to build an engine for the most horsepower they can afford; but is it worth it?

When building your engine, no matter the style: Inline, Small Block, Big Block, Carbureted, Fuel Injection, the biggest thing that needs to be considered is how the engine will be used. Is the car going to be a cruiser you hit the weekend cars and coffee with, or a bracket racer? These will be 2 completely different engine builds. The amount invested between these 2 will be vastly different too. But if built right the weekend cruiser would still give the drag car a run for its money between traffic lights. Put them both on an 1/8 or ¼ mile track and the drag racer will show you exactly where the extra money was spent.

The main difference is where the engine will live. The weekend cruiser is going to run in the lower end of your tach. It will red line usually around 6,000 rpm. The goal for this style build will be mid-range torque. If you can hit peak torque between 3200-4000 you have an engine that pulls hard at highway speeds. With the right gear-set out back; the simple cruise to and from the meet will keep a smile on your face the whole time. The drag car engine’s goal is to make top-end horsepower. Red line for this type of engine could climb up 7800 rpm or higher, that is if your pockets are deep enough. Don’t get me wrong this engine will still make great torque as well, but the rpm’s required to really get the motor going require very high stall speeds, or monstrous gears. Of course, there is a lot between these 2 engines. Once you figure out the rpm range your engine will live at, Match Your Parts!

Heads are the most mismatched parts in a build. A few factors will help determine what head to use. Engine displacement, desired compression ratio, vehicle weight and gear size being a couple. Most guys will look at airflow numbers and pick the largest head they can afford. This approach may rob you of power in the long run. Valves that are too large can hurt a street engines low-end torque. Large runners are good for boosted or high revving applications but will hurt velocity of an NA car. Both will affect throttle response. Spend time researching the heads as they will make up a pretty good chunk of your budget. You may gain more from a set of CNC ported heads then heads with the largest valves.

The cam shaft may be the heart of the engine, but it should not be at the top of the list of things to buy. Once you have your heads picked out you can look at cams. The head will help dictate the lift your cam can produce. It will also narrow down the rpm range the cam make power in. Most people will just want to buy the cam that has the most lift and largest duration. This combination will sound amazing but will suffer in the low and mid rpm ranges. Flat tappets hydraulic cams are tried and true. These are typically the cheapest option when buying a cam shaft. They are however limited by spring load and rpm. If not broken in correctly they can take out the entire engine. Roller cams are becoming more affordable. They allow you to run higher lifter and duration at more rpm. Either option is fine for street driven or cruisers. Hydraulic lifters can become unstable at rpms above 6,500 rpm. This is what is commonly referred to as floating the valves. If you plan on turning 7,000 + rpms a solid lift cam will take care of the instability. The downside is constant valve lash maintenance or engine failure could occur.

A dual plane or EFI intake are great catch all for any street cam. Most can build power from idle to 5500 rpm. They will also have a smooth idle and crisp throttle response, which is the reason most factory engines used them to begin with. Single plane intakes will make power in the higher rpm range 2500-7000, or narrower ranges 3000-7500. They accomplish this by using shorter, larger runners. These intakes can produce a rough idle and stuttering throttle response below 2,500 rpm. Your weekend cruised car will not benefit from an intake which doesn’t start making power until 3500 rpm. The intake manifold can have air speeds of up to 550 feet per second! Generally peak torque is created between 350-400 feet per second. Longer intake runner will create high air speeds and contribute to low-end torque. Short runners don’t allow air to speed up nearly as much but will create top end horsepower. As simple as an intake manifold is, many hours go into a design to move air the correct way for a desired power range.

All car guys know someone who has thousands of dollars into an engine which doesn’t perform like it should. What about someone who built a motor, drove it once, then pulled it to start over? Or the guy who decided to put the round track engine in his streetcar and can’t figure out why the mini van beat him off the line. The couple hours spent researching your engine build now can save you much more time and money in the future.